Garder les travailleurs en électricité hors danger : les outils sans contact – 2e partie

Deuxième de deux articles. La première partie a été publiée le 4 novembre.

La base de tout programme de sécurité en électricité est simple : limiter l’exposition des travailleurs aux risques que représentent les chocs et les arcs électriques. Faire des tests implique souvent de travailler à l’intérieur des panneaux sous tension pour faire des diagnostics ou pour des entretiens de routine. Les travailleurs qui font ces tests sont exposés à des dangers réels. L’équipement de protection individuel représente un obstacle aux chocs et aux arcs, mais ne peuvent constituer la seule et principale source de protection pour les électriciens et les techniciens. Des pratiques de travail sécuritaires, comme l’utilisation d’outils de test sans contact ne met pas les travailleurs en danger. C’est peut-être la première chose à considérer quand on parle de sécurité électrique.

Lire l’article …

This is the second in a 2-part series. Part 1 appeared in the November 11 issue of EIN, and discussed non-contact infrared (IR) thermometers, visual infrared thermometers, and infrared cameras.

Safe work practices, including the use of non-contact test tools that do not require electrical workers to place themselves in harm’s way, are the first line of defence when it comes to electrical safety. The last line: personal protective equipment (PPE). Read on to learn more about non-contact test tools that limit the exposure of workers to the electrical hazards of shock and arc flash.

Widening the safety window

Using an infrared (IR) window in conjunction with a thermal imager widens the safety envelope even further. Relatively small, circular IR windows can be permanently installed on enclosures that are part of the plant’s thermal imaging program, or can be mounted on equipment enclosures that may produce a dangerous arc flash should an accident occur while the door is open. By scanning through an IR window that is rated to withstand an arc flash and blast, it is not even necessary to open an enclosure door to scan.

As a result there is virtually no technician exposure to shock or arc flashes. It would be hard for routine maintenance and troubleshooting to get any safer! See Figure 3.

Figure 3. Using the IR Window to perform a thermal scan of equipment greatly increases safety for the thermal imaging technician. Shock and arc flash exposures are reduced to virtually zero.

Keeping your distance

One tool that is often overlooked when it comes to safety is the laser distance meter. Generally considered only a convenience item, this non-contact distance measurement tool also increases safety when doing such jobs as conducting an arc flash study. This engineering analysis requires measuring the lengths of conductor runs between equipment.

Rather than using steel measuring tapes and stepladders with two people finding themselves in precarious positions near and over cable trays and switchgear, the laser distance meter allows many distance measurements to be taken safely from the floor by just one person. Press the Measure Button once and the laser is activated. Then, point the laser to where the distance is to be measured and press the Measure Button again to read an accurate distance of up to 200 feet (61 meters) or more on the display.

Don’t make contact with an energized part

Non-contact voltage detectors allow voltages to be detected without having to make contact with an energized part. For quick power checks at a receptacle or troubleshooting a lighting circuit, using a voltage detector is safer than placing probes in a receptacle and much safer than opening boxes and lighting fixtures.

Users must be aware that voltage detectors will only indicate power on the ungrounded side of the circuit; not on the grounded or neutral conductor side.

Remote display

Remote display multimeters allow readings to be taken up to thirty feet (9 meters) away from the equipment being monitored. The display unit is removed from the multimeter while the meter and probes (or clamp) remain at the point of measurement.

Safety applications include closing the door on an MCC cubicle or disconnecting and standing at a safe distance to measure motor inrush current. Standing directly in front of a motor starter when a large

three-phase motor draws many times its normal running current at start-up is no place to be, even if wearing the appropriate PPE. Once again, the use of noncontact tools greatly reduces the personnel risk.

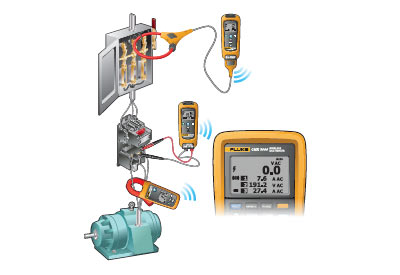

Wireless tools

Wireless tools provide the most advanced technology for enhancing safety. For example, you set up three remote modules at the equipment to be monitored. The digital multimeter (DMM) itself, with its display, can be held and observed at a safe distance more than sixty feet (18 meters) away, where it receives the wireless signals. If desired, up to ten readings can be downloaded real time wirelessly directly from the modules to a laptop.

Wireless tools are increasingly utilizing the cloud, where data goes from the tools to an app where data can be shared, stored, and viewed by your team from their laptop, tablet, or smart phone.

Technicians can stay well outside any shock or arc flash boundaries as equipment is operated and various parameters are observed and recorded. Many troubleshooting motor controls tasks are classed as Hazard Risk Category 2, requiring the use of an arc-rated face shield and balaclava. Once the modules are installed, the hazard risk category can be dropped to zero with the need for cumbersome faceshields, uncomfortable balaclavas, and bulky rubber insulating gloves all eliminated.

Taking several readings simultaneously helps minimize the need for workers to re-enter the limited approach and arc flash boundaries. See Figure 4.

Figure 4. Wireless test tools allow multiple readings to be made at a safe distance from equipment rather than in front of open enclosures. Multiple readings mean less time inside a live panel.

Summary

The use of non-contact test tools greatly limits and oftentimes completely eliminates the need for workers to be exposed to the electrical hazards of shock, arc flash, and blast. Probing inside a live panel with hands, test leads and clamps while attempting to locate measuring points, and then placing and holding test leads while turning and leaning to read a meter display, carries hazards. Many times two workers are required to accomplish this task, with the additional worker thus being exposed to the hazards. Providing a practical safe working area free of electrical hazards is the stated purpose of electrical safety standards.

The use of non-contact test tools can help achieve that goal and create an electrically safer and more efficient work environment for employees.

Source: Fluke Digital Library @ www.fluke.com/library.