Des stratégies gagnantes pour une modernisation de votre éclairage DEL

Les entrepreneurs et les gestionnaires sont de plus en plus conscients des avantages que procure la technologie DEL. La qualité de l’éclairage, la consommation énergétique moins importante, une durée de vie plus longue, sont tous des avantages connus. « Les gens sont intéressés par cette technologie parce qu’ils peuvent économiser de l’énergie et sauver ainsi de l’argent » explique Ed Garraway, président de Garraway’s Electrical Services in Midland en Ontario.

Pouvoir offrir des consultations sur des mises à niveau DEL est une opportunité intéressante pour les distributeurs et entrepreneurs en électricité. Ils peuvent ainsi se distinguer de la concurrence et devenir experts dans ce domaine. Développer une expertise dans les avancées touchant l’éclairage moderne est une façon de se démarquer. Voici des points importants pour développer cette stratégie.

Contractors and facility managers have become increasingly aware of the advantages of LED technology. Light quality, low energy consumption, and longer lamp life are well-established benefits of modern LEDs. “People get motivated because they save energy and that translates to money in their pockets,” says Ed Garraway, president and founder of Garraway’s Electrical Services in Midland, Ontario.

Consulting on LED retrofit strategies presents an opportunity for distributors and electrical contractors (ECs) to set themselves apart as experts in this field. Demonstrating an expertise in modern lighting advancements makes a powerful impact on customers. Saving them money and conserving energy increases customer loyalty and your revenue.

Sizing Up the Project

Begin by developing a detailed project plan, including identifying potential complications. Our experience is that electrical contractors and their customers may face some of the following challenges in LED retrofitting.

Fixture Replacement In the past, it’s been common to replace existing fixtures with entirely new LED luminaires. Total fixture replacement is complicated and expensive, making it difficult to forecast costs. For example, this process may additionally require all new mounting systems, conduit, and electrical fittings, possibly impacting the effectiveness of the structure.

HID Ballast This replacement option may also present problems as LEDs are generally ineffective with an HID ballast. This process could require wiring around the ballast. However, the ballast may not be easily accessible — it may be enclosed within a ceiling or wall, for example. Thus, the entire fixture may need to be taken out, creating additional renovation considerations.

Architectural Integrity and Design Aesthetics must be taken into account when embarking on an LED upgrade project. The original architectural integrity and design of the space could be negatively impacted by the changes. It may be difficult, for example, to find replacement fixtures that compliment the original design.

Dimming Capability Before deciding on an LED replacement option, functional aspects such as the dimming capability should be considered. Not all LED lamps are compatible with dimming technologies. Hence, if dimming is critical in the location, an LED retrofit may not be effective.

Directionality HID lamp bulbs glow in every direction, while LEDs are directional, pointing light in a specific direction. Therefore, it’s necessary to understand the output coverage from the fixture in order to determine whether the replacement will be successful in the space. Directionality may impact the number of lights required along with their precise placement. For instance, fewer lamps may be needed if the light is directed to specific areas that need to be illuminated — an additional savings for the customer.

Presenting an Estimate

While the energy saving aspect of LED lighting is attractive, making the switch may pose significant challenges. Depending on the replacement strategy, upgrading to LED technology may require a significant investment in design and capital improvements in order to install new fixtures, resulting in a lengthier wait to achieve ROI.

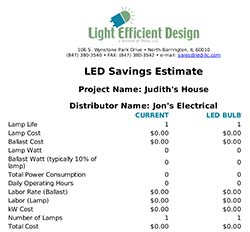

We recommend presenting a thorough financial summary to the customer, including an estimate of comparable costs. Figure 1 shows a comprehensive list of costs. In the early stages of a project, this list can be a useful guide to review with the client. (NOTE: INSERT COST COMPARISON CHART.)

Know Your Lamps

Below is a detailed checklist to aid in the lamp selection process.

Lamp size and base type Check the sizes of the lamp and base, as they must be compatible. HID lamps are relatively small, while LED lamps tend to be larger.

Voltage Check the voltage and keep in mind that Canada is the only country in North America that uses 120-347V.

cUL-certification Many LED lamps are cUL-certified for dry locations, but not damp. If the installation involves post-tops or garage lights, for instance, it will be prudent to use damp-certified lamps. Furthermore, many products are cUL-certified for open air only usage. Lamp life expectancy will be significantly reduced when using products that are not rated for enclosed fixtures. “There are many manufacturers of LED lamps and a lot of them sell non-CSA or UL-listed products,” warns Ed Garraway. “You have to be sure to install approved lamps and fixtures.”

Research the Manufacturer Choosing an established manufacturer that provides a full line of LED lamps designed for demanding commercial and manufacturing applications is a critical step in the replacement process. Working with less reliable manufacturers can force you to source lamps from multiple suppliers. Matching lighting colors and lamp styles from various suppliers can be time-consuming and costly. Furthermore, sticking with one established manufacturer ensures that warranty maintenance will be less complicated. “Doing your homework may take a little time, but it is worth it,” Garraway emphasizes.

Download the LED Comparison Chart

To Kit or not to Kit

Given the cost and complexity of fixture replacement, contractors often rely on retrofit kits. Such kits typically replace the entire fixture housing and may also replace some optics and lenses. Retrofit kits represent an upfront investment, but generally they perform safely and well.

Fortunately, there is now an effective alternative to retrofit kits: high-quality LED retrofit lamps that replace costly HID systems while maintaining existing lamp fittings. Self-contained LED retrofit lamps bypass the ballast and screw in directly. This simple, energy and cost saving option enables faster, easier installation and provides a quicker ROI, often less than two years.

Retrofitting with self-contained LED lamps has several significant benefits. First, it’s budget-friendly. Customers don’t need to tackle an entire costly project all at once. Instead, they can retrofit in area by area or even lamp by lamp in budget-manageable phases.

Retrofitting in phases or lamp by lamp also avoids shutting down sites entirely during a project. Business can go forward without interruption of production and operations. When you’re retrofitting lamp by lamp it’s also easy to do trial runs of just a few LED lamps. The customer can assess different lamp temperatures and choose what works best for their space.

For many customers, the fact that self-contained LED retrofit lamps leave their existing fixture untouched is an advantage. The original aesthetic and design of their space is maintained and they don’t incur additional design expense.

The simplicity of the installation of self-contained LED Retrofit lamps is another notable benefit. You simply bypass the ballast and screw the lamp in. It’s fast and efficient!

Lastly, an LED retrofit takes roughly the same amount of time as an HID re-lamping. So, if a customer is committed to the timeline, transforming with LED lamps will improve light quality and save money in the long run.

LEDs and Heat Management

Quality thermal (heat) management is essential to the optimal functioning of LED products. LED product life span is significantly shortened without reliable thermal management.

The utilization of LED products in larger, more complex commercial applications has presented new challenges for effective thermal management in LED design.

Previously, LED products were used primarily in smaller applications and functioned with passive cooling technologies, like heat sinks, which create more surface area to absorb heat.

Although such applications proved to be successful, more complex LED applications require a combination of passive and active cooling technologies in order to supply proper thermal management, thereby maintaining optimal LED life and performance .

Specifically, an LED lamp of greater than 20W needs an active cooling mechanism to be effective over time. An active cooling system prevents the LED lamp from heating up until the point that the electronics fail.

Active cooling fans are the most reliable and effective option. Fans lower the temperature by forcing air across the components.

Fans have been successfully implemented through several product generations by high-tech manufacturers like Apple, IBM, and HP. They have proven to be reliable and unobtrusive in servers, desktops, and laptops by effectively cooling within compact spaces.

The key LED product design goal is heat reduction, ensuring optimal performance. High quality thermal management distinguishes superior LED lamps from inferior technologies.

A Bright Future

LED retrofitting assists customers in their efforts to reduce energy consumption and costs while maintaining favorable aesthetics. LED is the lighting solution for a sustainable future. Once customers experience the LED transformation they won’t look back.

About the Author

Jon Fredrikson, Director of Marketing for Light Efficient Design, has nearly 10 years of experience in the electrical and lighting industry. Prior to joining Light Efficient Design, Jon held a variety of marketing and national sales positions at Intermatic, Inc.