La nanotechnologie : Améliorer l’efficacité des moteurs électriques

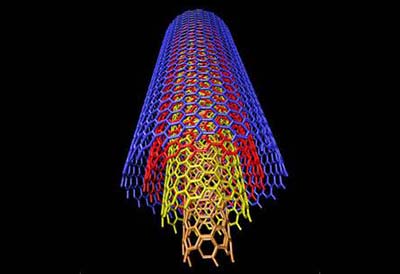

L’Université de Technologie de Lappeenranta (LUT) a dévoilé le premier moteur électrique qui utilise le fil de nanotubes de carbone, en remplacement des fils de cuivre dans les enroulements. Ce moteur est une étape vers des moteurs électriques légers et efficaces. Sa puissance de sortie est de 40 W; la vitesse de rotation, 15 000 tours par minute.

« Les machines électriques ont un potentiel d’amélioration significatif. Néanmoins, compte tenu de la physique des matériaux, des matériaux traditionnels ont atteint leurs limites », croit le Dr Marcin Otto, Business Development Manager pour Teijin Aramid, une société japonaise néerlandaise qui a développé la technologie pour tourner des fils de nanotubes de carbone en collaboration avec l’Université Rice, É.-U.. « Les matières de carbone peuvent être la solution : la conductivité des fils de nanotubes de carbone peut être de trois fois celle du cuivre. En outre, le carbone est abondant tandis que le cuivre doit être exploité ou recyclé par des procédés industriels. »

Lappeenranta University of Technology (LUT) has unveiled the first electrical motor applying carbon nanotube yarn, replacing copper wires in windings. The motor is a step towards lightweight, efficient electric drives. Its output power is 40 W; rotation speed, 15 000 rpm.

“Electrical machines have significant improvement potential. Nevertheless, considering material physics, traditional materials are reaching their limits,” says Dr. Marcin Otto, Business Development Manager for Teijin Aramid, a Japanese-Dutch company that has developed the technology for spinning carbon nanotube yarns in collaboration with Rice University, USA. “Carbon materials may be the solution: the conductivity of carbon nanotube yarns could be three times that of copper. Further, carbon is abundant while copper must be mined or recycled by industrial processes.”

Aiming at upgrading the performance and energy efficiency of electrical machines, Professor Pyrhönen is testing higher-conductivity wires as windings. Here, new technology may revolutionize the industry. The best carbon nanotubes (CNTs) demonstrate conductivities far beyond the best metals.

”If we keep the design parameters unchanged, only replacing copper with carbon nanotube yarns, the Joule losses in windings can be reduced to half the present machine losses. With lighter and more environmentally friendly CNT yarn, we can reduce machine dimensions and CO2 emissions in manufacturing and operation. Machines could also be run in higher temperatures,” says Professor Pyrhönen.

No upper limit for conductivity

Traditionally, electrical machine windings are made of copper, having the second best conductivity of metals at room temperature. Despite copper’s high conductivity, most machine losses occur in copper windings. Carbon nanotube yarn, instead, does not have a pre-defined upper limit for conductivity (values of 100 MS/m measured on individual CNTs).

According to Pyrhönen, electrical machines are so ubiquitous that we often forget their presence. In our homes there can be countless electrical machines. “An industrial facility may include thousands of motors, all with copper windings. Thus, finding a more efficient material would revolutionize the industry.”

Carbon replaces copper?

Industrial applications are still in their infancy, but increasing the production capacity and the yarn performance will allow major steps forward in developing innovative products, believes Teijin Aramid’s Dr. Marcin Otto.