L’impact des arcs électriques sur les systèmes de commandes d’éclairage

L’adoption de l’éclairage LED continue à un rythme rapide. Bien que la durée de vie prolongée des DELssoit une donnée positive, ces nouvelles options présentent également un défi de compatibilité avec les anciens systèmes de contrôles, en particulier avec les photocontrôles extérieurs. Ce changement rapide dans les technologies d’éclairage DEL peut laisser les entrepreneurs, les concepteurs et les distributeurs face à des questions auxquelles ils ne peuvent pas répondre. Les DELs et autres technologies d’éclairage utilisent exclusivement des conducteurs électroniques et des ballasts pour fonctionner. Leurs conceptions ont des caractéristiques différentes de démarrage électrique que celles des anciens modèles magnétiques.

The adoption of LED lighting continues at a rapid pace. Although the extended life of LEDs is beneficial, it also presents a compatibility challenge with older technology controls, especially without door photo controls. This rapid change to LED fixtures and luminaires can leave contractors, designers and distributors facing questions they cannot answer.

LED and other new lighting technologies exclusively use electronic drivers and ballasts for operation. Their designs have different electrical start-up characteristics than older, magnetic models. In the case of photocontrols, matching the extendedlifespan of LED fixturesrequires a more complex control unit for a reliable, turn-on/off.

Design considerations for electronic ballasts

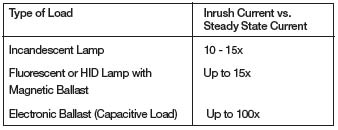

A more complex control unit isrequiredbecausesomeelectronic ballasts produceinrushcurrentsatturn-on thatcan cause prematurerelay contact failures. Intermatic has completed simulations in our UL-certifiedlaboratory and has videotaped the phenomena of thisspike of energy. This energyspikecan and has caused control failures in the field. Theseinrushcurrentscanbemuchhigherthanthoseexperiencedwithtraditionaltungsten or magnetic ballast loadsbecausemanyelectronic ballasts employ large energystoragecapacitors. Suchcapacitorscan charge up to 400V for a 277 V line voltage, and willbrieflydrawhighcurrentfrom the line to achievethis voltage.

As mentioned above, these typically short in rush currents can climb as high as 100-times the nominal operating levels. (See table below for typical inrush value comparisons.)

An overlooked source of photocontrol failure

Inrushcurrents have not always been recognized as a source of failure for controls. Some contractors may mistakenly believe that a switch has failed because it’s a “bad” switch or a power surge has occurred. Jay Hoch, Lighting Specialist for Wyandotte Electric Supply, Wyandotte, Michigan, noticed photocontrol failures on a large, exterior LED lighting project in Detroit. “We had multiple fixtures on one circuit fail, but not all of the fixtures failed. That didn’t make anysense. If one failed, they all should.” Hoch was looking for an explanation and wondering how best to advise the contractor coming to him. Information on in rush currents supplied by Intermatic made sense of the performance of the controls that Hoch and the contractor had noticed. After reviewing the information, Hoch realized that in rush currents were adversely impacting the controls. “The failure wasn’t in the circuit,” Hoch says. “Intermatic’s research solidified the fact that the in rush current affects photo cells.”

Variances in inrushcurrent

The in rush current magnitude and duration depends upon the value of the capacitance (measured in μF), along with circuit and power distribution network impedances. This current may weld relay contacts and other switching devices or possibly fuse semiconductors. Overall, these high-current transients can negatively impact the lifespan of traditional photocontrols, negating the reduced maintenance cost associated with LED luminaires.

Therefore, the actual performance of electronic ballasts can’t be determined by a straight watt-to-watt comparison of incandescent bulbs to LED bulbs. At first glance, it may make sense to assume that ten 15 W LED bulbs could be substituted for a single 100 W incandescent bulb. However, an in rush current in the LEDs can negatively impact the control, causing failures over time.

If contractors don’t look at the specs for the controls, they may believe when a switch fails it’s a bad switch. However, providing proper control specifications would enable contractors to avoid failures that are caused by very high in rush currents.

New electronic ballast designs can provide low or zero in rush currents, but they are more costly to implement and have not been universally adopted by lighting manufacturers in the marketplace. This created a challenge for control suppliers. Hearing questions from distributors and contractors, Intermatic chose to design electronic photocontrols for worst case in rush currents, as characterized by the National Electrical Manufacturers Association (NEMA)’s survey of electronic ballast technologies.

In Part 2, photocontrol design solutions to minimize the effects of high in rush currents.

Source: Intermatic Incorporated, 7777 Winn Road, Spring Grove, IL 60081; 815-675-2321; www.intermatic.com/zerocross. Intermatic’s new line of electronic photocontrols for LED applications successfully utilizes zero crossing techniques to suppress in rush current impact and deliver on the extended lifespan of LED luminaires. As a result, Intermatic offers cost effective, 8 to 12 year warrantied electronic photocontrols, while providing large in rush current carrying capacities. Lab testing shows the visible reduction of in rush current, which Intermatic has captured on video.