D’autres changements au Code canadien de l’électricité 2015

En poursuivant sur le thème des changements à venir dans le Code canadien de l’électricité 2015, je voudrais ici mettre l’accent sur l’ajout de règles pour la zone de classification CEI pour les environnements contenant des poussières.

Si vous vous souvenez, c’est le Code de 1998 qui a introduit de zones de classification pour atmosphères explosives gazeuses. L’introduction de la zone 0, zone 1 et zone 2 a donné lieu à de nombreuses questions au sujet des marques et la façon dont ces marques devaient être interprétées. Après tout, l’industrie était familière avec le système de division de marquage, qui informe l’utilisateur du Code sur l’endroit où l’appareil est autorisé à être installé par opposition au système CEI, marqué avec les types de protection utilisés, et c’était à l’utilisateur du Code de déterminer à quel endroit l’équipement pouvait être installé sur la base des types de protection.

This is the second of two parts. The first part appeared in the August 26 issue of EIN.

In continuing with the theme to provide insight into the changes that will appear in the 2015 Canadian Electrical Code (CE Code), I would like to focus on the addition of rules for the IEC Zone method of area classification for environments containing dusts.

If you recall it was the 1998 CE Code that saw the introduction of the zone area classifications for explosive gas atmospheres. The introduction of Zone 0, Zone 1 and Zone 2 resulted in many questions with respect to markings and how those markings should be interpreted. After all, the industry was familiar with the division system of marking, which instructed the code user on where the equipment was allowed to be installed as opposed to the IEC system, which was marked with the types of protection used, and it was up to the code user to determine in which location the equipment could be installed based on the types of protection.

The main reason for proceeding with these changes was to continue the harmonization efforts between CE Code Section 18 and the IEC Zone method of area classification and associated installation practices. Adopting these rules and methods of classification should also remove trade barriers and open equipment selection options for industry across Canada.

In the latest change, Section 18 will see the introduction of Zones 20, 21 and 22 to replace the division system of area classification for dusts, fibres and flyings (Class II and Class III). Zones 20, 21 and 22 are the IEC designations for hazardous locations involving dusts. Existing CE Code requirements associated with Class II and Class III locations have been moved into Appendix J. This move will retain the rules for the division system of area classification (flammable gases, dust, fibres and flyings) together in one appendix to accommodate legacy installations.

Specific terminology has been defined to assist the code user with the new requirements and to align with Canadian adoption of the IEC 60079 series of standards. The term “dust” is used as a generic term and includes both combustible dust and combustible fibers. Both terms “combustible dust” and “combustible fibers” are further defined based on particle size (dust being 500 μm or smaller and fibre being greater than 500 μm), which allows combustible dust to present a fire or explosion hazard when dispersed and ignited in air while combustible fibres may be suspended in air and could settle out of the atmosphere under their own weigh. Combustible dust also includes definitions for “conductive” and “non-conductive” dust as one being combustible metal dust and the other being combustible dust other than combustible metal dust.

“Equipment Protection Level (EPL)” is also defined in the new 2015 edition CE Code. This term was first introduced in the 2012 edition CE Code in Rule 18-052 and was explained in the Appendix B note to that rule. EPLs are required marking for any hazardous location electrical equipment certified to the IEC 60079 series of standards adopted in Canada in 2011. EPL is the level of protection assigned to electrical equipment based on its likelihood of becoming a source of ignition. EPL marking for electrical equipment suitable for explosive dust atmospheres are “Da”, “Db” and “Dc.”

EPL Da is marked on equipment having a very high level of protection. This equipment is not expected to be a source of ignition during normal and abnormal operation. Abnormal operation for EPL Da equipment includes expected malfunctions and rare malfunctions.

EPL Db is marked on equipment having a high level of protection. This equipment is not expected to be a source of ignition during normal and expected malfunctions.

EPL Dc is marked on equipment having an enhanced level of protection. While this equipment is not expected to be a source of ignition during normal operation, it may have additional protection associated with it to ensure that it does not become a source of ignition during expected malfunctions.

The last definitions that need to be reviewed are those providing insight into what makes up Zones 20, 21 and 22 locations. If you are familiar with the zone descriptions associated with explosive gas environments (Class 1), the same reasoning is used for dust environments:

• Zone 20 locations — clouds of dust exist in the air, forming an explosive dust atmosphere frequently or for long periods of time

• Zone 22 locations — clouds of dust exist in the air forming an explosive dust atmosphere during normal operation occasionally

• Zone 22 locations — clouds of dust exist in the air forming an explosive dust atmosphere that is not likely to occur during normal operation and if it does will only persist for a short time

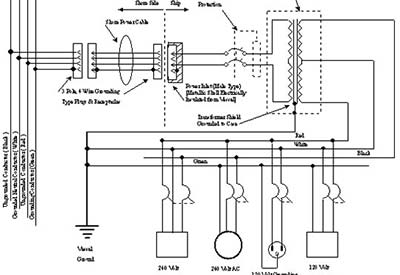

With the above definitions in place, rules can be established for equipment, wring methods and sealing for all three zones. There is no need for specific requirements for receptacles, luminaires, transformers, etc. in these locations as all the equipment should have markings associated with the IEC requirements. For example, in a Zone 20 location, it is recommended that electrical equipment not be installed within the environment. If it must, then it shall be suitable for Class II, Division 1 locations; or provide EPL “Da”; or provide one or more of the following protection level, intrinsically safe type “ia”; encapsulation “ma”; or protection by enclosure “ta”.

Wiring methods allow for Rigid Metal Conduit and “HL” Cables. Provisions are also provided for equipment that requires a flexible connection (liquid-tight flexible conduit with fittings suitable for the application, or extra-hard-usage flexible cord and cable glands suitable for the application). Seals are required to ensure dust does not enter enclosures that are required to be dust tight, and there are a few methods available to the code user outside of an actual permanent and effective seal. For Zone 21 locations, the list of equipment that can be installed is expanded to include Zone 20 markings as well as anything marked EPL Db, or equipment that provides one or more of the following protection levels, intrinsically safe type “ia” or “ib”; encapsulation “ma” or “mb”; or protection by enclosure “ta” or “tb”; or pressurized enclosure “pxb” or “pyb”. It is clear that as the likelihood of a hazard is reduced the options available for equipment and wiring methods increase, also evident by the requirements for Zone 22.

For the purpose of this article I’ve simplified the requirements mandated for Zone 20, 21 and 22 locations in the previous paragraph. As the industry has had to deal with changes to IEC methods back in 1998, these should not pose as much of a shock. I really believe code users will have no problems initiating these changes when their prospective jurisdictions adopt the 2015 CE Code.

Pierre McDonald, CET, is Senior Regulatory Affairs Representative/Répresentant Principal, Affaires Réglementaires, Underwriters Laboratories of Canada Inc. Based in St. Albert, AB, Pierre has been a member of the Canadian Electrical Code Part 1 technical committee as well as several subcommittees including serving as Chair of Sections 6 and 76 and as a member representing regulators on several other CSA committees. Pierre is still active with code development and interpretation.